Bolt manufacturer – a wide range of products tailored to market needs

Bolts are one of the key components in many industrial sectors. They are essential in construction, automotive, machinery, and even electronics. As a fastener manufacturer with long-standing experience, we offer top-quality products that meet strict technical standards and customer requirements.

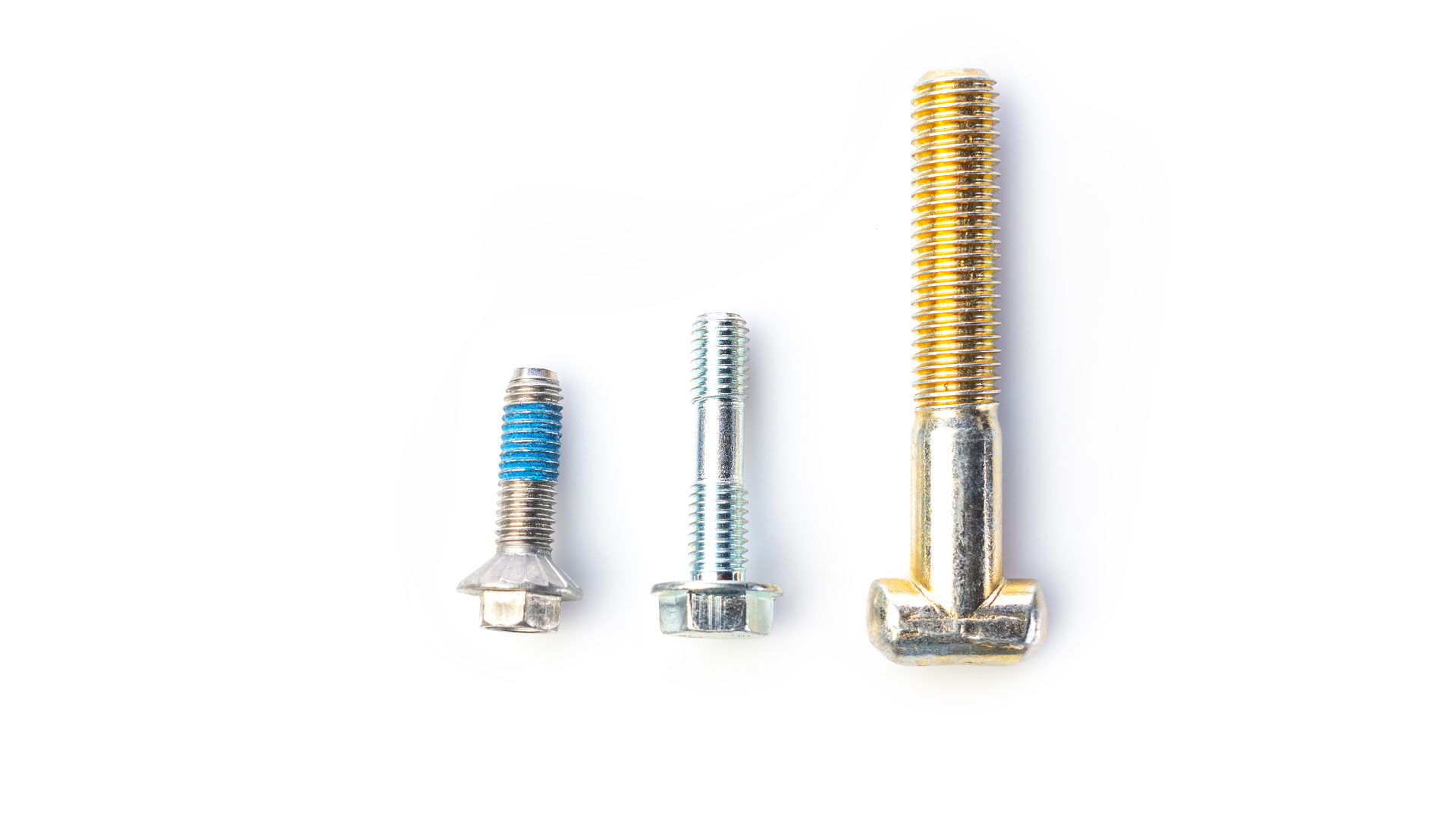

Our offer includes a wide range of screws divided into two main categories: standard and special fasteners.

Standard screws – the solid foundation of our operations

Standard bolts have been our business cornerstone for years. As a fastener manufacturer, we understand how crucial it is to meet the highest quality standards. Therefore, our products are made according to the international standards such as ISO, DIN or PN, which ensures their full compliance with the requirements of the global market. These parts are widely used in many industries, from construction to precision mechanics.

Thanks to precise manufacturing processes and advanced technology, we guarantee that our products are not only durable but also resistant to corrosion and external factors – key for long service life and reliability.

Additionally, we offer bolts in various sizes, lengths and thread types – enabling perfect adaptation to every client’s needs.

Special parts – an innovative approach to modern solutions

Technology development and rapidly changing market trends required us to adapt our offering to more demanding projects. In response, we expanded our production into special products.

Previously, complex shapes of fasteners were only possible through machining – time-consuming and waste-producing. Today, we manufacture such parts using waste-free cold forming.

Scrap-free cold forming – the key to precision and sustainability

Cold forming without material loss allows shaping metal without scrap. This makes our production more ecological and efficient. The process enables complex shapes with outstanding durability. This is made possible through precise control of the material deformation process, resulting in products with excellent technical parameters.

We work with a wide range of materials such as carbon steel, stainless steel, copper, brass or aluminium. Each of these requires a tailored approach, which is why we constantly improve our technologies to meet evolving expectations. Our special parts are used in demanding engineering projects where standard products cannot meet specific requirements.